Line for bottling carrot-based puree juices into bottles - capacity up to 5,000 bottles/h - 0.33 l

Line for bottling carrot-based puree juices into bottles - capacity up to 5,000 bottles/h - 0.33 l

Contact us for price

Location:Siemyśl, Poland

Description

Line for bottling carrot-based puree juices in bottles - efficiency up to 5,000 bottles/h - 0.33 l. CIP washing station

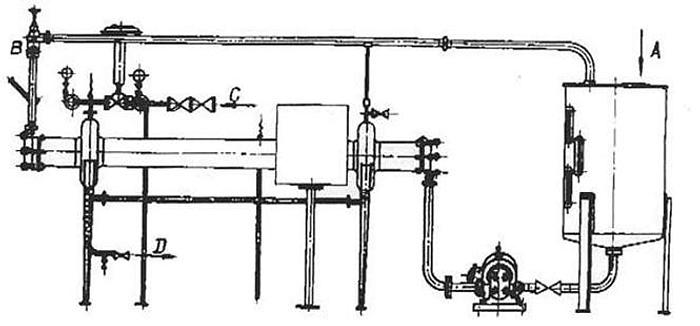

I. CIP washing station.

1. CIP washing station TETRA-PAK Dimensions: * Total length (station with one tank) – 2,480 mm; * Total width – 1,300 mm; * Total height – 2,100 mm. Technical data: * Station manufacturer – Tetra Pak, Lund, Sweden * Main circulation pump: - Manufacturer – Alfa-Laval, LKM A/S, Koding, Denmark; - Type – 1.162 SSS 4 kW * Year of production - 1995 * Heat exchanger: - Alfa-Laval - Type – M6-MFM - Year of production – 1995 - Max. Working pressure – 10 bar * Control cabinet with full automation; * Control – Alfa-Laval SattCon05 Slimline controller; * Distribution of control via valve island to pneumatically controlled valves; * Water tanks: - Quantity – 2 pcs. - Tank dimensions – 980mm x 1,200mm x 990mm - Tank volume – approx. 1,100 l * Mixing pumps: - Producer – BRAN+LUEBBE, Germany; - Type – DS 200/144 - Efficiency – 200l/h - Max. working pressure – 10 bar. * Cleaning agent tank: - Dimensions - height 1,610, diameter - 480 mm; - Volume – approx. 180 liters.

2. Clean water tank for rinsing – capacity 1,000 l; Rectangular stainless steel tank with mixer, insulating jacket and coil, capacity 1,057 l External dimensions: * Length – 1,180 mm; * Width – 1,180 mm; * Height – 1,600 mm. Internal dimensions: * Length – 885 mm; * Width – 885 mm; * Height – 1,350 mm.

Technical data: Total capacity – 1,057 l. II. Line for syrup preparation and juice preparation and pasteurization; 3. Syrup tank with mixer; Stainless steel boiler with coil for heating or cooling mixed raw material Dimensions: * Total width - 1,500 mm; * Total height - 2,400 mm. Technical data: * Weight - 540 kg; * Total capacity of the boiler - 1.85 m3; * Boiler working capacity - 1.3 m3; * Type TZA 33 Spomasz Pleszew; * Propeller mixer; * Mixer drive - engine - 1.5kW - 950 U/min; * Working pressure of steam in the coil - 3 atm; * Oval-conical bottom - bottom drain. 4. Blending tank; Storage and process tank with a slow-speed frame mixer and a heating and cooling jacket with thermal insulation, capacity 2,500 liters Dimensions: * Diameter - Ø 1.670 mm; * Height - 2,700 mm. Internal dimensions of the tank: * Diameter - Ø 1,400 mm; * Depth - 1,800 mm. Technical data: * Capacity - 2,500 l; * Frame mixer, slow speed; * Upper hatch; * Sloping bottom; * Bottom drain valve * Water connection to the heating and cooling jacket - threaded pipe 5. Buffer tank with mixer – capacity 4000 l;

Horizontal tank type FK-40, capacity 4,000 l Dimensions: * Total length - 2,460 mm; * Total height - 2,300 mm; * Tank diameter - 1,750 mm. Technical data: * Capacity - 4,000 l; * Power of the engine driving the mixer reducer - 0.6 kW - 1,440 U/min; * Weight - 1,060 kg 6. Tubular pasteurizer;

Tubular pasteurizer - "WPA 8" It is used to heat (sterilize) purees and concentrates vegetables and fruits at a temperature of 40 - 90 ° C.

Technical data: * Working steam pressure - 1.5 atm; * Steam temperature - 126 °C; * Process temperature - 95 °C; * Steam demand - 200 - 300 kg/h; * Capacity of the intermediate tank - 630 dm3; * Capacity of the pressure space - 130 dm3; * Capacity - 1,500 kg/h; * Net weight - 815 kg; * Weight during operation - 1,450 kg; * Parts in contact with the product - acid-resistant steel; * Other parts - carbon steel. Purpose and diameter of the stubs in the drawing above: * Product feed - 50 mm; * Steam exhaust - 25 mm; * Condensate drain - 25 mm. 7. Tubular Container: Tubular holder – stainless steel Dimensions * Length - 1.530 mm; * Width - 380 mm; * Total height - 1,400 mm; * Working height - 1.030 mm. Technical data: * Throughput - 10,000 l/h; * Capacity - 77 or 87 l; * Hold time - 31.6 s; * Type - RH 25; * Year of production - 1983 or 1986; * 8 levels of pipes with a diameter of 65 mm; 8. Deaerator; Tiltable deaerator Dimensions: * Total cross-section of the deaerator - Ø 800 mm; * Height - 1,750 mm. Technical characteristics: * Vacuum - max. 960 hPa; * Working vacuum - 200 - 300 hPa; * Capacity - 5,000 l/h; * Working volume of the tank - 270 l; * Cooling water flow - 200 l/h; * Lamp supply voltage - 24 V; * Power supply - 1.5 kW; * Max. degassing temperature - 80 °C. 9. Homogenizer; Homogenizer "Rannie" Homo - Mic Dimensions: * Length - 1,380 mm; * Width - 860 mm; * Height - 1,200 mm. Technical data: * Engine: - Power - 11 kW; - Revolutions - 970 U/min; * Working pressure - up to 250 atm; * Capacity - up to 2.5 tons. 10. Pumps - 3 pcs; "GA13" pump Dimensions: * Length – 450 mm; * Width – 300 mm; * Height – 370 mm. Technical data: * Engine power - 1 kW - 2,900 U/min; * Capacity - 16,000 l/h. III. Juice bottling line and package forming and packaging line 11. Bottle washer; Washing of closed packaging (cans, jars, cups, etc.) with drying Dimensions: * Total length - 3.050 mm; * Total width - 1,180 mm; * Total height - 2,100 mm. Technical data: * Tape width - 200 mm; * Smooth regulation of belt speed; * Made of: completely stainless steel. 12. Steam bottle heating device; Dimensions: * Total length: 2,800 mm; * Total width: 700 mm; * Total height: 1,700 mm. Technical data: * Entry/exit gate light: 330mm/190mm; * Mains water connection; * Width-adjustable conveyor with two V-belts; * Conveyor drive – gear motor; * Water circulation pump; * Mesh filter; *Steam water heating. 13. Juice filling machine for bottles; "LAB 4" bottling machine The machine is used for pouring food products, e.g. milk, concentrated juices, purees, etc. for bottles or containers with a capacity of 250, 500, 1000 cm³.

Dimensions: * Length - 1,400 mm; * Width - 1,100 mm; * Height - 2.060 - 2.120 mm. Technical data: * Capacity adjustment range - 1,800 - 3,600 bottles/hour; * Number of pourers - 10; * Packing machine drive - electric motor; * Power W=0.75 kW; * N = 1,400 U/min; * Capacity of filled bottles - 250, 500, 1,000 cm³. 14. Capping machine; Jar closing machine "TWIST-OFF" type ZSG-1, "TREPKO" (UNIPAK) Dimensions: * Total length - 2,800 mm; * Width - total - 1.050 mm; * Total height - 2,260 mm. Technical data: * Operating capacity - 3,500 - 7,000 pcs/h; * Jar diameter range - 50-130 mm; * Jar height range - 60-250 mm; * Lid diameter range - 52-94 mm; * Weight - approx. 1,000 kg; * Power supply - 220V/380V - 50 Hz - 1.87 kW; * Steam demand - 30-50 kg/h; * Steam pressure - 0.2 - 0.4 MPa; * Water demand - 100 l/h. 15. Spray pasteurizer; Immersion and spray pasteurizer - "NIKO" Dimensions: * Total length - 9,500 mm; * Working length - 9.000 mm; * Working width of the belt - 1.165 mm; * Total width of the belt - 1,240 mm; * Total width of the pasteurizer without the feeding and receiving conveyor - 1,600 mm; * Total width with feeding and receiving conveyor - 2,400 mm; * Height of the pasteurizer without the gear motor - 1,500 mm + 700 mm height of the gear motor. Technical data: * Steam power - open system; * Steam demand at start-up - 400 - 500 kg/h; * Steam demand during operation - 200 - 600 kg/h; * Thermoregulation of steam supply with simultaneous control of water temperature; * Pasteurizer tank capacity - approx. 3,000 l; * Smooth regulation of belt speed; * Pre-heating and pre-cooling spray pump - engine - power 2.2 kW - 1.440 * U/min; * Pasteurization spray pump - engine - power 2.2 kW - 1,440 U/min; * Belt drive motor with smooth speed control - power 0.25 kW - 680 U/min, output speed * - 0.6-3.3 U/min; * Loading belt drive motor - power 0.55 kW - 1,440 U/min. (belt speed * constant); * Unloading belt drive motor - power 0.55 kW - 1,440 U/min. (belt speed * constant); * Efficiency for 0.9l jars - 1,200 pcs/h (with a 30-minute total pasteurization process); * Has 4 sections; * Preheating section - 600 mm - spray. * Proper pasteurization section - 5,000 mm - spraying and immersion; * Pre-cooling section - 2,100 mm - spray; * Cooling section - 650 mm - spraying with well water or externally cooled water; * Passive zone at the entrance - 290 mm; * Passive zone at the exit - 360 mm. 16. Bottle dryer; DRYING TUNNEL TS 800/3/ST for packaging after washing, e.g. canned food in cans, jars, etc. Dimensions: * Length – 3,460 mm; * Width – 1,450 mm; * Height – 1,700 mm. Technical data: * Producer - POLIMET Zbigniew Polit, Tywonia, Poland; * Year of production - 2019; *No. serial - 2092019-TS8-3; * Tape width – 800 mm; * Tape length – 3,450 mm; *Stainless steel wire braided tape; * Belt driven by gear motor; * Controlled belt speed – 0.5 – 10 m/s; * Length of the heating zone – 2,530 mm; * Heating zone divided into 3 independent zones; * Each zone is separately controlled and powered from a separate phase; * Air duct with ventilation spigot and valve along the furnace; * Power supply – 3 x 230 V; * Power consumption – 15 kW; * Maximum operating temperature – 180 ̊C. 17. Labeling machine; Automatic labeling machine - "ECA 06" The machine is used to apply labels to cylindrical containers such as bottles, jars, cans, etc. Dimensions: * Length - 2.500 mm; * Width - 900 mm; * Height - 1,170 - 1,320 mm; Technical data: * Manufacturer - PZL Świdnik; * Type - ECA 06; * Height of the apron conveyor belt from the ground - 950 - 1,100 mm; * Efficiency - 3,000, 4,000, 6,000 packs/h; * Packaging diameter - min. 50 - 100 mm, up to 90 mm - gluing all around; * Gluing height from the bottom of the package - 5 mm; * Label length - 70 - 290 mm; * Electric motor - SF 90 S4; 1.1 kW, 1,415 U/min. * No. - 1381; * Weight - 512 kg. 18. Package forming and wrapping unit; BAT-FORUM machine for forming into packets and foiling. Dimensions: * Width – 2,400 mm; * Depth – 1,550 mm; * Height – 2,100 mm. Technical data: * Producer – BAT FORUM, POLAND * The current equipment allows the creation of a package with the following parameters: * Number of rows of containers – 3; * Max. package width – 230 mm; * Maximum package height – 345 mm; * Maximum package length – 400 mm, * Width of the belt feeding containers – 250 mm; * Feeding belt design - modular, made of plastic * Length of the heating cut-off strip – 700 mm; * Length of the lower and upper foil feeding rolls – 770 mm; * 2 foil feed roller drives and 2 conveyor drives - total power approx. 1 kW * Actuators moving the package onto the heating strip, moving the heating strip and pressing - pneumatic; * Adjustment of the width, length and height of the package - manual; * Control – electronic; * Execution: - Frame – painted carbon steel; - Covers – painted carbon steel, stainless steel; - Partitions separating containers into rows - stainless steel; - Covers for the foiling chamber - plexiglass and lacquered carbon steel strainers. 19. Package shrink tunnel; Dimensions: * Width: 970 mm; * Length: 3.000 mm; * Height: 1.680 mm; Technical data: * Polish production * Heating chamber length - 1,100 mm; * Heating chamber entrance height - 398 mm; * Total width of the heating chamber inlet - 595 mm; * Width of the installed stainless tape – 530 mm; * Belt feed speed regulated by an ABB inverter * Bottom, top and side heaters * Convection fans: lower and upper (power 0.06 kW) * Cooling fan: horizontal with adjustable flow direction. * Made of: frame – carbon steel, housing – stainless steel. 20. Pallet wrapper; "GEMA" pallet wrapper Dimensions: * Total length: 2,400 mm; * Total width: 1,500 mm; * Total height: 3,200 mm. Technical data: * Diameter of the pallet platform: 1,500 mm

Specifications

| Condition | Used |

| Stock Number | LN1007 |