20-POSITION LINE FOR MANUALLY APPLICATION OF RAW MATERIAL VEGETABLES, FRUIT, ETC. FOR PACKAGING OF DIFFERENT SIZE AND WEIGHT JARS, CANS, PLASTIC PACKAGING

20-POSITION LINE FOR MANUALLY APPLICATION OF RAW MATERIAL VEGETABLES, FRUIT, ETC. FOR PACKAGING OF DIFFERENT SIZE AND WEIGHT JARS, CANS, PLASTIC PACKAGING

Location:Siemyśl, Poland

Description

20-position line for manual application of raw materials (vegetables, fruits, etc.)

to containers (jars, cans, plastic containers) of various sizes and weights The line consists of: a) Two independent modules, each equipped with a fixed worktop (stainless),

150-200 mm wide, combined with a movable conveyor (PU) of raw materials with a width of 150-200 mm fed with raw material fed from the bunker (with a

specially adapted (stainless) hopper to receive raw material from boxes-pallets

or other containers and to separate it raw material for two conveyors) - added to the modules; b) 82 mm wide, oppositely movable plate conveyor (KO or PE) with rails adjustable

to120 mm wide, made of closed profiles that can withstand the pressure of empty

packages (empty packages ordered from rotary tables served by the end workstation); c) Between two identical (symmetrical) modules set up an independent plate conveyor

(KO or PE) collecting filled packages from workstations. Description of the symbols of scheme I and II: A - Fixed work table for 10 positions

- length - 9.000 mm; B - Feeder for transporting raw material

- length - 9.000 mm; C - Conveyor for transporting empty packages

- length - 9.000 mm; D - Conveyor for transporting filled packages

- length - 13,000 mm; feeding the filled packages

to the next one devices in the processing line); E - Turntable feeding empty packages onto the feeder C

- diameter - 1,000 mm; F - Charging bunker - sending the raw material to the feeder B (arrows indicate the

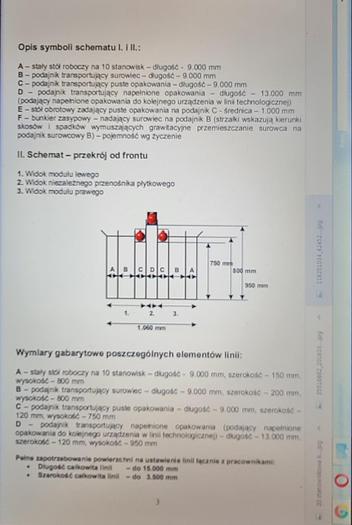

directions of slopes and slopes;gravitational movement of the raw material to the raw material feeder B) - capacity as requested. Diagram - front view: 1. View of the left module; 2. View of the independent plate conveyor; 3. View of the right module 750 mm A B C D C B A 800 mm 950 mm;

1. 2. 3. 1.060 mm. Overall dimensions of individual line elements - A - Fixed work table for 10 positions: - Length: 9,000 mm; - Width: 150 mm; - Height: 800 mm. B - Feeder transporting the raw material: - Length: 9,000 mm; - Width: 200 mm; - Height: 800 mm. C - Conveyor for transporting empty packages: - Length - 9,000 mm; - Width - 120 mm; - Height - 750 mm. D - Feeder transporting filled packages (feeding the filled packages to the next

device in the line technological): - Length: 13,000 mm; - Width: 120 mm; - Height: 950 mm. Full space requirement for setting up the line, including employees: • Total line length: up to 15,000 mm; • Total line width: up to 3,500 mm.

Specifications

| Condition | Used |

| Stock Number | LN1013 |