French fries production line with a capacity of up to 5 t/h of raw material

French fries production line with a capacity of up to 5 t/h of raw material

Contact us for price

Location:Białokury, Poland

Description

French fries production line with a capacity of up to 5 t/h of raw material I. FEMIA 2-chamber washer and descaler with a threshold receiving conveyor Dimensions:

- Total length – 6,450 mm;

- Total width – 2,190 mm;

- Total height – 2,400 mm.

Descaling chamber: Overall dimensions

- Length – 4,280 mm

- Width – 2,190 mm;

- Height – 1,700 mm.

Internal dimensions:

- Length – 4,000 mm;

- Width – 1,240 mm;

- Depth – 1,390 mm.

Drainage chamber: Overall dimensions

- Length – 2,320 mm

- Width – 1,860 mm;

- Height – 880 mm.

Internal dimensions:

- Length – 840 mm;

- Width – 1,500 mm;

- Depth – 600 mm.

Threshold receiving conveyor:

Dimensions:

- Belt length – 2,700 mm;

- Belt width – 670 mm;

- Threshold height – 70 mm;

- Threshold width – 600 mm;

- Spacing between thresholds – 170 mm.

Technical data:

- The water circulation system consists of 5 circuits powered by 1 collector, the turbulent water

movement is generated by nozzles located on the piping of individual circuits

- Water pump - power 10 kW;

- The raw material is transferred from the descaling chamber using a water stream from the nozzles,

and it is collected via a water jet belt conveyor with threshold (drainage) belt

- Bathtubs and conveyor made of stainless steel

- Construction of a water circulation system – galvanized steel pipes

II. Potato drum washer with water spray: Drum made of acid-resistant steel, housing made of acid-resistant steel, structure - carbon steel.

Dimensions:

- Length – 5.100 mm;

- Width – 1.200 mm;

- Height – 2.500 mm.

Technical data:

- Installed power - 1.5 kW;

- Capacity max. – up to 5000 kg/h;

- Water demand – 4000 l/h;

- Drum revolutions – 12 U/min;

- Drum diameter - 900 mm;

- Drum length – 3.800 mm;

- Weight – 1.775 kg.

III. Weighing and steam pressure scalding unit with a thresholds feeder or raw materials Dimensions:

- Total length - 10,500 mm;

- Total width - 3,400 mm;

- Total height - 5,100 mm.

The team includes the following devices:

- Loading conveyor onto the weigher - threshold - modular belt;

- Length of the charging part – 1,300 mm;

- Length of the rising part – 5,900 mm;

- Length of the discharge part – 500 mm.

- Width - 750 mm;

- Lifting height - 6,000 mm;

- Threshold height - 70 mm;

- Spacing between thresholds - 110 mm;

- Raw material portion weigher - strain gauge;

- Belt width - 800 mm;

- Belt length – 1.700 mm;

- The valve opens with a pneumatic actuator

- Dimensions of the scalding unit:

- Length – 4.500 mm;

- Width – 3.400 mm;

- Height – 3.800 mm;

- Height with weigher – 5.100 mm;

- Steam infuser (pear) Universal 600:

- Manufacturer - Paul Kuntz CO GmbH, Germany;

- Capacity of the pressure infuser - 800 l;

- Operating pressure of the infuser - up to 14 atm;

- Steam consumption per 1 kg of raw material - approx. 0.3 kg;

- Length of the raw material brewing cycle - depends on the steam pressure;

- Feed - opening and closing - steam actuator;

- Hopper for the scalded raw material;

- Screw receiver - unloading from the chute;

- Screw length – 2.200 mm;

- Screw cross-section - 300 mm;

- Steam expansion tank - 1000 l;

- Set of automatic valves and pressure piping;

- Capacity up to 6 t/h;

- Entirely made of stainless steel.

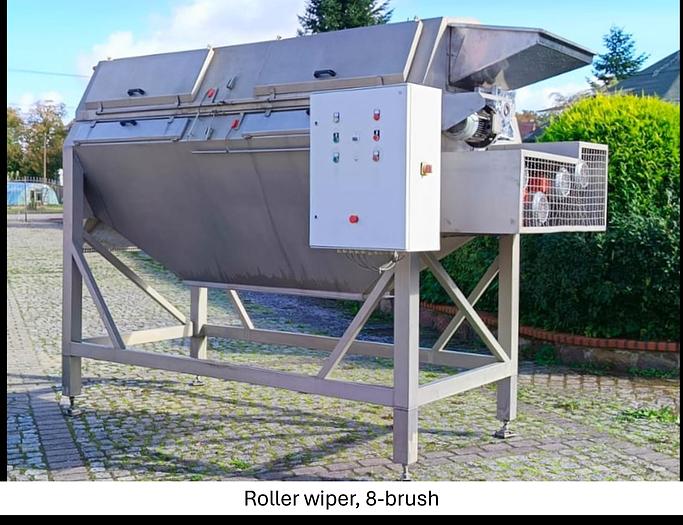

IV. Roller wiper, 8-brush Dimensions:

- Length – 3,970 mm;

- Width – 1,900 mm;

- Height – 2,680 mm;

Technical data:

- Producer – MEGA Bełżyce;

- Year of production – 2010;

- Roller length – 3,000 mm;

- Brush rollers driven by four motors with geared motors;

- Power of each engine – 1.5 kW;

- Screw drive – approx. 3kW;

- Weight of the device – 1,200 kg.

V. Inspection table Overall dimensions:

- Length - 6,200 mm;

- Width – 1,300 mm;

- Height – 1,900 mm (with lighting)

Technical data:

- Polyurethane belt - white;

- Belt length – 6,000 mm;

- Belt width - 800 mm;

- Height to the working surface of the belt - 1,250 mm (adjustable ± 400 mm;

- Motor – gear motor – 0.57 kW – 1,310 U/min;

- Four illuminating lamps;

- On four swivel wheels;

- Made entirely of stainless steel.

VI. Descaler with an inclined conveyor

Overall dimensions:

- Total length - 4,950 mm;

- Total width - 1,400 mm;

- Total height - 1,570 mm.

Technical data:

- Dimensions of the descaling tank:

- Bathtub length - 2,000 mm;

- Bathtub width - 800 mm;

- Bathtub depth - 520 mm;

- Bathtub height - 970 mm;

- The raw material is transferred from the descaling chamber using a

horizontal water stream forced by a circulation pump and a rotary paddle selector;

- Dimensions of the inclined receiving conveyor:

- Length - 1.800;

- Width - 750 mm;

- Height - 1,850 mm.

- Made of: fully stainless steel.

VII. Urschel slicer Dimensions:

- Length - 1.850 mm;

- Width - 2.200 mm;

- Height - 1.760 mm.

Technical data:

- Producer - Urschel;

- Model - Q (QuantiCut Dicer);

- Maximum dimensions of the cut product - 254 mm (in each direction);

- Engine power - 7.5 kW;

- Efficiency depending on the cutting size – 6 - 10 t/h;

- Hinged lids and sliding lids provide easy access and simplify cleaning;

- Prepared for continuous operation;

- Cuts - slices, bars, cubes;

- Very easy replacement of knife systems - by 1 person;

- The machine is used for cutting various types of vegetables - potatoes, carrots, beets,

turnips, parsley, celery, pineapples, peppers and many other types of vegetables;

- Current equipment for the cube – 10x10x10 mm (LxWxH);

- Made of stainless steel.

VIII. Separator of shorts and trimmings after cutting potato tubers into French fries

Overall dimensions:

• Length – 3,100 mm;

• Width – 1,400 mm;

• Height – 1,500 mm

Technical data:

• Length of the orientation table – 1,200 mm;

• Length of the receiving table – 730 mm;

• Has 36 orientation paths;

• Magnetic vibrators – 2 pcs;

• Vibrator operation controlled by an inverter and diodes;

• Frame and gutter made of stainless steel;

• Vibrator stabilizer – painted steel.

IX. Threshold feeder from the slicer to the blancher Dimensions:

- Total length - 4,000 mm;

- Total width - 1,250 mm;

- Dump height - 2,400 mm;

Technical data:

- Loading height - 600 mm;

- Threshold belt, polyethylene;

- Tilt angle - 45°;

- Working length of the belt - 3,800 mm;

- Total width of the belt - 420 mm;

- Working width of the belt - 300 mm;

- Height of drivers - 80 mm;

- Distance between drivers - 450 mm;

- Drive - motor drum;

- Drip gutter under the belt;

- Construction - stainless steel;

- All swivel wheels with locks.

X. Blancher for pre-blanching of French fries, Mather &Platt Dimensions:

- Total length - 5,100 mm;

- Total width - 2,100 mm;

- Total height - 2,630 mm.

Technical data:

- Producer - S.A. Mather & Platt, Paris, France;

- Bowl length – 4,100 mm;

- Bowl cross-section – 1,900 mm;

- Filling cross-section - Ø 400 mm;

- Discharge cross-section – Ø 400 mm;

- Steam power - open system - V-shaped pipes with holes along the entire length of the bowl;

- Possibility to measure the temperature at the input and output of the raw material;

- Water level overflows in the bowl (right and left);

- Bottom drains in the bowl - in the front and rear parts;

- Water supply from the front at the hopper and in the middle part of the right side of the bowl;

- Top strip with hooks to lift the hood;

- Drive power - 2.2 kW - 1,440 rpm (Bauknecht);

- Transmission with smooth speed regulation;

- Gear manufacturer - Ruba Fabrik;

- Made of stainless steel.

XI. Feeding conveyor from the pre-blanching blancher on the Cabinplant final blanching machine Dimensions:

- Total length – 4,860 mm;

- Total width – 822 mm;

- Total height – 1,000 mm.

Technical data:

- Producer – Cabinplant, Denmark;

- Working length of the belt – 4,700 mm;

- Working width of the belt – 400 mm;

- Plastic modular tape;

- Drip gutter;

- Made of completely stainless steel.

XII. Final blanching blancher Mather & Platt Dimensions:

- Total length - 5,100 mm;

- Total width - 2,100 mm;

- Total height - 2,630 mm.

Technical data:

- Producer - S.A. Mather & Platt, Paris, France;

- Bowl length – 4,100 mm;

- Bowl cross-section – 1,900 mm;

- Filling cross-section - Ø 400 mm;

- Discharge cross-section – Ø 400 mm;

- Steam power supply - open system - V-shaped pipes with holes along the entire length of the bowl;

- Possibility to measure the temperature at the input and output of the raw material;

- Water level overflows in the bowl (right and left);

- Bottom drains in the bowl - in the front and rear parts;

- Water supply from the front at the hopper and in the middle part of the right side of the bowl;

- Top strip with hooks to lift the hood;

- Drive power - 2.2 kW - 1,440 rpm (Bauknecht);

- Transmission with smooth speed regulation;;

- Gear manufacturer - Ruba Fabrik;

- Made of stainless steel.

XIII. Fan dryer - stainless steel

The device is used to dry products after blanching, with air forced by five fans distributed evenly along the entire length of the device. Overall dimensions:

- Total length - 6,350 mm;

- Total width - 1,100 mm;

- Height 1,440 (with control box - 1,600 mm)

Technical data:

- Belt width - 800 mm;

- Belt working length - 6,250 mm;

- Feed dimensions:

- Width - 800 mm;

- Length - 450 mm;

- Depth - 200 mm;

- Fans for drying the product - 5 pcs. (radial);

- Power of one fan - 0.18 kW. - 1,440 rpm;

- Belt drive power - 0.75 kW with smooth feed adjustment;

- Belt feed speed adjustment by means of an inverter;

- Equipped with side inspection covers;

- On four wheels - two swivel with locks;

- Belt - mesh, stainless;

- Made of - stainless steel.

XIV. Fryer NON The oil in the frying tub is heated by a tubular heater using thermal oil. Heater performance adjusted to the energy demand of the fryer. Dimensions :

- Total length - 7,400 mm;

- Total width - 2,000 mm;

- Total height - 2,650 mm.

Technical data:

- Efficiency - up to 3 tons/h when frying products;

- Hydraulic system for lowering the frying tub and lifting the upper cover of the fryer;

- The frying tub, top cover and horizontal structure made of stainless steel;

- Legs made of carbon steel - varnished and covered with stainless steel;

- Stainless steel control box: belt drive, hydraulic drive, bathtub lifting/lowering,

circulation pump drive oil; oil temperature control;

- Tape width - 1,000 mm;

- Depth of the frying tub including the tubular heater - 700 mm.

Equipped with:

- Frying oil circulation pump;

- Oil strainer;

- Peripheral oil tank approx. 2300 l

XV. Cooler for fries after frying Overall dimensions:

- Total length – 6,400 mm;

- Total width – 1,113 mm;

- Total height – 1,500 mm.

Technical data:

- Belt – mesh – stainless steel;

- Belt length – 6,150 mm;

- Belt width – 730 mm;

- Belt drive - motor – 0.37 kW;

- Smooth belt feed regulation;

- Raw material feed at a height of – 1,250 mm;

- Raw material discharge at a height of – 900 mm;

- Fans for drying the product - 5 pcs. (radial);

- Power of one fan – 0.18 kW. – 1,440 rpm;

- Equipped with side inspection covers on both sides;

- Equipped with a drip tray with four drains;

- Adjustable leg height;

- Made of stainless steel.

XVI. Feeder for the freezing tunnel. Dimensions:

- Length – 4,340 mm;

- Width – 1,170 mm;

- Dumping height - 3,000 mm;

- Filling height - 1.000 mm.

Technical data

- Working belt width – 970 mm;

- Distance between drivers – 200 mm;

- Drive height – 50 mm;

- Adjustable legs;

- Has a drip gutter;

- Made of stainless steel.

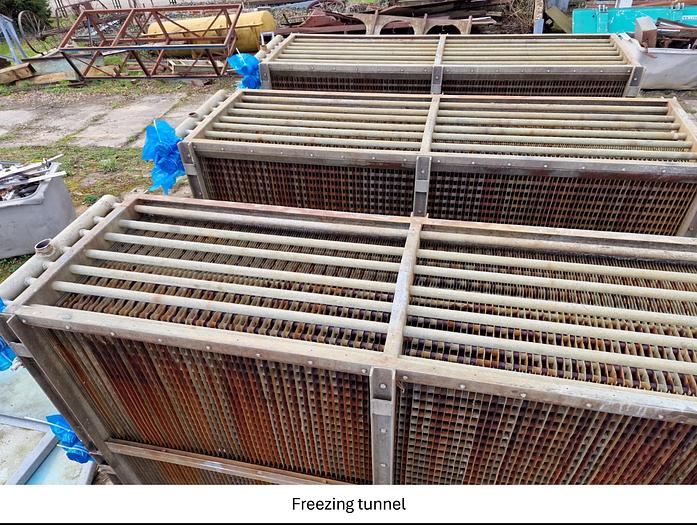

XVII. Justus Starfrost Freezing Tunnel Dimensions:

- Total length - 14,000 mm;

- Total width - 5,700 mm;

- Total height - 4,500 mm.

Technical data:

- Producer - Justus Starfrost;

- Model - Turbo Twin Pass 86.5;

- Capacity at +21°C / -18°C - approx. 6,000 kg/h (green peas);

- Required cooling power - 780 kW at 6,000 kg/h of peas;

- Refrigerant - NH3, pumped;

- Evaporation temperature - -34°C at the evaporator outlet;

- Total number of fans – 7 pcs.

- Pre-freezing zone fans - 3 x 11 kW;

- Freezing zone fans - 4 x 11 kW;

- Number of evaporators - 3;

- Size of evaporators - 1.1 m³;

- NH3 power connection – fi. 60.3mm;

- NH3 suction connection – fi. 114.3mm;

- Belt drive - 2 x 0.75 kW;

- Water demand for defrosting - quantity: 40 m³/hour; temperature: +20°C; pressure:2 bar;

- Water requirement for washing the belt - quantity: 1.7 l/sec; pressure: 2 bar;

- Total installed power - 82 kW;

- Total length - 14,000 mm;

- Tape width - 1.520 mm;

- Mesh tape (stainless steel) - 72-24-16 mm.

Specifications

| Condition | Used |

| Stock Number | LN1021 |